PERFECTION IS HAVING THE RIGHT SOLUTION FOR EVERY PRODUCT.

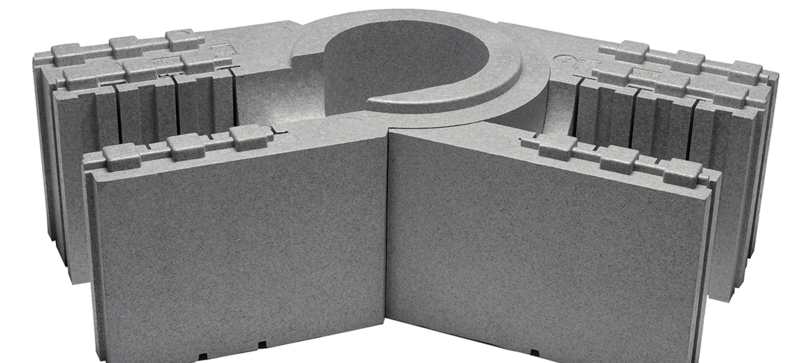

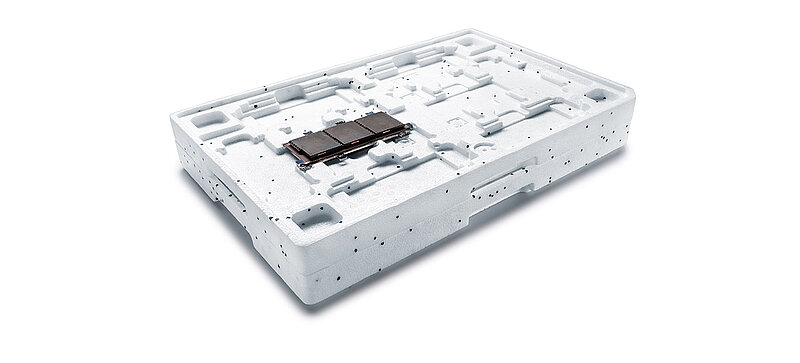

Storopack has been developing and manufacturing technical molded parts in line with customer requirements for a number of decades. The material we use for this purpose is expanded polystyrene (EPS), known as Styropor®, Piocelan®, Neopor®, and polypropylene (EPP). Each of these four synthetic materials has special properties that make it suitable for certain applications. EPS, for example, is very light, consists of up to 98 percent air, and reliably protects products such as electronic components from damage. With its graphite component, meanwhile, Neopor® provides even better insulation than EPS against heat and cold. EPP, on the other hand, is extremely durable, making the molded part very long-lasting. Piocelan® marries the strengths of EPS and EPP in one material and is used wherever these properties need to be combined.

The big advantage of expanded plastic foam is that it is very light and can be flexibly formed. At the same time, technical molded parts can be used in various densities. They also have outstanding insulation properties and reliably absorb shocks, making them very versatile. Our designers produce solutions that are used in a wide range of industries, such as the automotive, construction, and HVAC sectors, as well as for leisure products and as a design material. We work with you to find the optimal solution, tailored to your individual needs.

Not currently available in Australia.

Storopack Australia Pty Ltd

17 Prince William Drive

NSW 2147 Seven Hills

T +61 2 9674 3355

![[Translate to International:] Zwei weiße technische Formteile als Gießtrauben für Lost-Foam-Verfahren](/fileadmin/_processed_/9/f/csm_PP_L_cover_pump_with_negative_7417_low_res_01_de91af0ce1.jpg)