rEPS MEANS CUSTOMIZED YET SUSTAINABLE PACKAGING.

With rEPS (recycled expanded polystyrene), we want to protect your products and the planet by fully closing the recycling loop for EPS protective packaging. Our alternative to EPS consists of a minimum of 95 percent recycled EPS/PS waste where both, post-industrial (PIR) and post-consumer (PCR) waste is used – which is certified by RecyClass. With this, Storopack sets a new industry benchmark for mechanical recycling, making us the first EPS manufacturer to achieve this high standard.

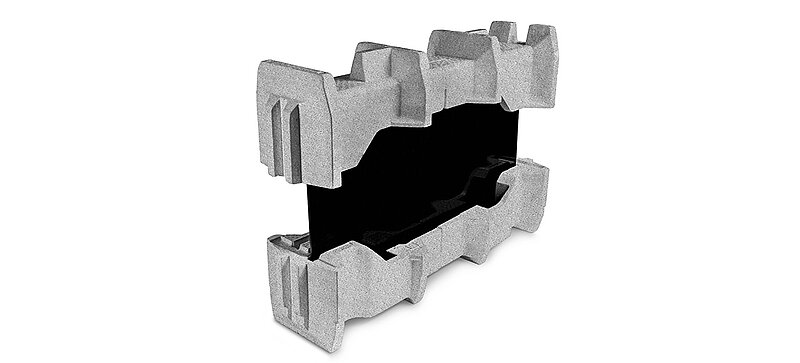

Our rEPS solutions can be used to produce new protective packaging with up to 100% of the recycled raw material and are available in white and grey. Designed to avoid loose beads thanks to its strong connection and non-friable properties, rEPS solutions are ideal for classic protective packaging for household appliances and electronics, temperature-controlled packaging for pharma and non-food applications, as well as construction. As such, rEPS represents an exceptionally attractive solution for companies that wish to ship their goods precisely and safely while taking sustainability seriously.

rEPS FOR PACKAGING AT A GLANCE

- Consists of minimum 95% recycled EPS/PS waste, RecyClass certified

- Protective packaging can be produced with up to 100% rEPS

- Simple and efficient cycle for EPS protective packaging

- Available in white and grey, maintaining virgin EPS properties

- Strong connection to avoid loose beads

- Ideal for protective packaging, pharma and temperature-controlled packaging, non-food and construction

Storopack Australia Pty Ltd

17 Prince William Drive

NSW 2147 Seven Hills

T +61 2 9674 3355

![[Translate to International:] Eine weiße maßgeschneiderte Schutzverpackung aus recyceltem EPS](/fileadmin/_processed_/4/8/csm_PP_rEPS_Box_3108_1280x580px_01_3ddd9cf1fa.jpg)

![[Translate to International:] Eine Mini-Spülmaschine mit einer grauen maßgeschneiderten Schutzverpackung aus recyceltem EPS](/fileadmin/_processed_/e/2/csm_PP_E_rEPS_Mini_Dish_Washer_0750_1280x580px_1972910bb1.jpg)